Silica Fumes for Concrete: Increase The Performance And durability Of Concrete

When it comes to construction materials, concrete is surely one of the most important materials that can be used mainly due to it’s inherent strength properties. But it is the addition of some materials or additives that change the property of concrete. It not only makes it more durable in nature but it also increases the performance of concrete as a construction material.

With so many new constructions that are taking place, the demand for high performance concrete is increasing day by day. One of the important additives that are used during with concrete is silica fumes for concrete.

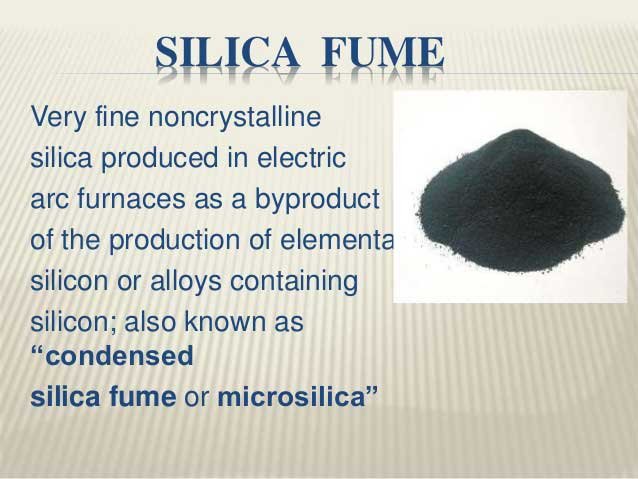

What is silica fume?

Micro-silica or silica fumes are a non-crystalline polymorph. They are extracted from silicon dioxide. It is a very fine powder that is collected as a by-product from the ferro-silicon alloy and silicon production. It is mainly used as a pozzolanic material in the high-performance concrete.

How does Silica Fumes for Concrete contributes to the strength and durability?

Silica fumes in concrete helps in strengthening and maintaining the durability of concrete in two ways:

- As a pozzolanic material, silica fumes provide a uniform distribution and a greater volume for the hydration products.

- As filler silica fumes decreases the size of the pores in the cement paste.

The effectiveness of the silica fumes as a pozzolanic material and as a filler material depends largely on the composition and the particle size which in turn depends on the composition of the raw materials as well as the design of the furnace. Silica Fumes has unique chemical and physical properties which is why micro-silica is a really versatile mineral additive which can be used in a multitude of applications.

Silica Fumes Application in Concrete

Due to its unique chemical and physical properties, silica fumes can be used in a wide range of applications.

- Silica fumes for concrete have reduced permeability which means that the chloride salts cannot penetrate into the building structure and corrode the steel. Therefore, they provide a protection against the intrusion of the chloride salts and increases the durability of the building.

- It has a high chemical resistance and a low permeability which provides for a higher protection against the sulphates than other sulphate resisting concrete.

- If you were to replace cement with the silica fumes and observe the efficiency factor of the silica fumes, then a lower maximum temperature rise along with the temperature differential will take place for the concrete having same strength. Therefore silica fumes help in heat reduction.

- Silica Fumes have really low levels of permeability which is why it is a great material to be used to water-proof the buildings.

- Silica fumes when used with super-plasticizers provides for a really high strength concrete.

- It also has high abrasion resistance, due to which it is used on the streets and the pavements. This helps save a ton of time and money.

- Micro silica is used widely in industrial buildings that are prone to damage from chemicals and other acids.